It is no secret that the screen print industry is vast and extremely unique. We have been in the business for 85 years… and we are still investigating and applying new technologies!

While not always intentionally misleading, you’re often absorbing content from:

Printers who have limited capability: Most printers don’t have both screen and digital printing capabilities which can lead to biases.

Printer’s experience: Large format screen printing is very exclusive, and most printers do not have the vast knowledge that can only be acquired from screen printing for decades.

Marketers without much print experience: Marketers wear multiple hats and juggle numerous projects at once; it would be unreasonable to rely on them to know everything!

Non-practitioners: Printers who don’t invest in R&D themselves, but pass along (sometimes outdated) printing insights they’ve read online.

Outdated Information: Technologies, substrates, and capabilities change every day. Mechanics that weren’t possible yesterday, could be possible today.

We have completed thousands of prototypes, produce millions of graphics yearly, and have helped secure multiple government contracts with our screen printing expertise – here are 17 myths we have compiled over the years that you may have been told about large format screen printing.

1. Digital printing is the only way to print a high quality white ink

False. Screen printed white lays down a thick ink film that produces far more opaque, bright, and quality white ink than digital printing could achieve. We have even developed a high performing custom white formula, see here.

2. Screen printing can’t always match difficult colors

False. With screen printing, you are only limited by your imagination. We like to say if your eye can see it, we can hit it.

3. Screen printing is not as precise as digital printing

False. Screen printing is extremely precise and is often used in the OEM, industrial, medical, electronics, and government markets to achieve more precision than digital can accomplish.

4. Screen printing is only for bulk orders

False. Although making the screens requires more steps than sending a digital file to a printer, screens are archived to be reused, eliminating additional setup and art prep costs for repeat orders.

In addition, there are colors or special effects that the digital gamut can’t hit. With our diverse capabilities, we can employ a hybrid process. This flexibility provides you with multiple options for utilizing both processes within a project! Printers without this range of offerings have to outsource production, adding time and cost, as well as increased emissions and carbon waste for additional transportation.

5. Screen printing can’t accurately hit small type

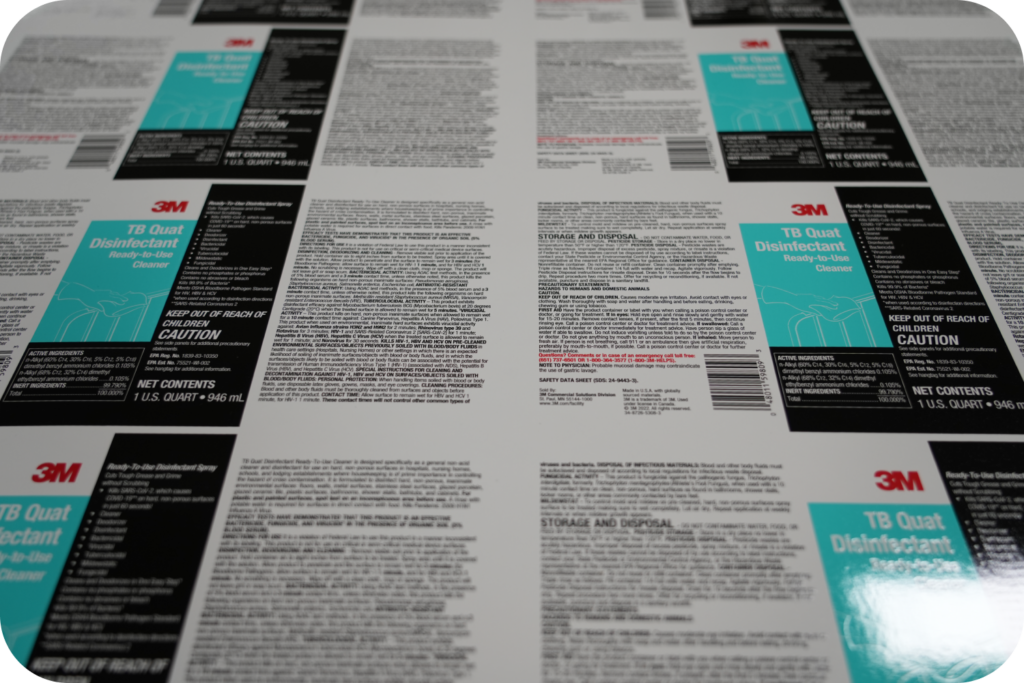

False. We have been able to screen print down to a sharp 4pt type. Digital processes are limited in substrates and longevity. For example, the customer below required a decal durable enough to withstand extreme chemicals.

6. Screen printing fades over time

True. Well, sort of… all printed inks do eventually fade. However, due to the heavier film deposited by the screen printing process, ink quality diminishes much more slowly. Knowing this is a critical factor for particular use cases we have partnered with specific suppliers, allowing us to offer warranties on certain printed parts. For example, we offer a 7 year 3M™ MCS™ Warranty on specified graphic products, guaranteeing they will not fade outdoors for almost double the standard time frame expectation [depending on location]. This inevitably reduces the overall cost by increasing a fleet’s life cycle substantially.

7. My turnaround time will be longer if I use screen printing

False. While screen printing has a longer setup time than digital, Modernistic has developed efficiencies to reduce those operations. We have invested in highly skilled, experienced technicians (40+ years!), an award winning ink formulation lab, a state of the art direct-to-screen process, and one of the most extensive large format screen printing selections in the US – all dedicated to producing thousands of printed parts every day. Naturally, longer run quantities obtain even more efficiencies via screen printing.

8. Screen printing inks are not environmentally friendly

False. Many ink manufacturers offer sustainable alternatives from renewable resources (i.e. water based inks, soy based inks, algae based inks, vegetable oil based inks). We are actively developing sustainable alternatives to help reduce our carbon footprint. If you would like to quote a project with some of these – feel free to ask.

9. Screen printing has a low ROI

False. Screen printing has tons of room to increase your bottom line. It also helps to have a vendor invested in comprehensive and lean manufacturing methods. Finding efficiency in a project is how we help our customers increase their bottom line. Whether that’s engineering new automation for our machines, setting up a reorder process, or finding ways to increase product durability, our mission is to increase value to you, the customer.

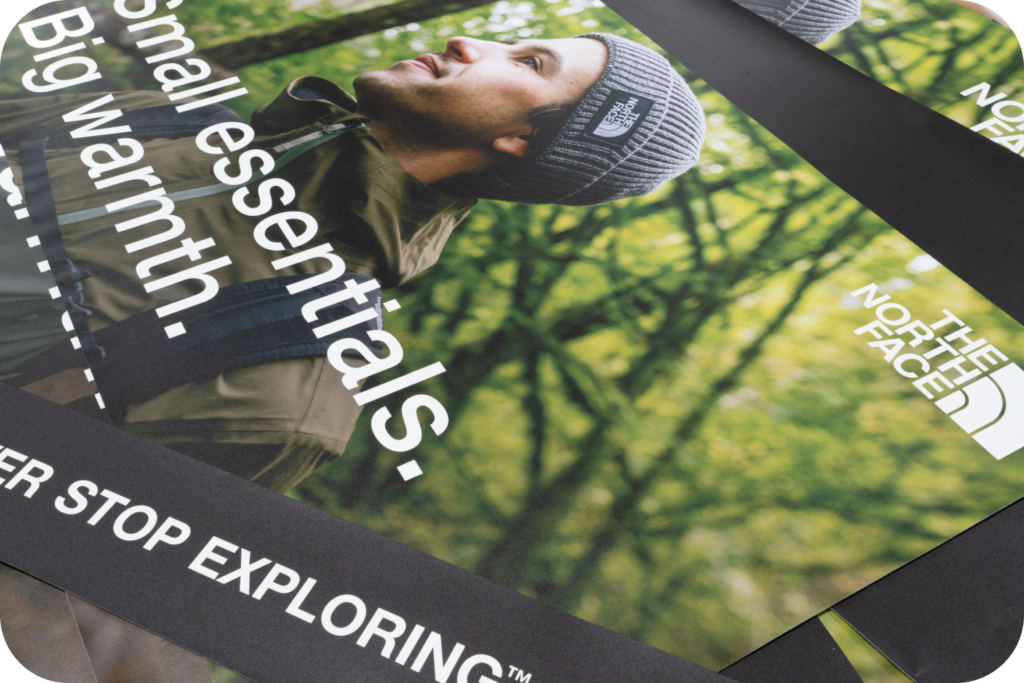

10. Screen printing is only effective for fleet graphics

False. The benefits that make screen printing a popular choice for fleet decals can carry over to any other industry. For example, when a retailer has a new seasonal promotion and requires thousands of new window graphics, screen printing is going to be the most cost-effective option.

11. You can’t screen print on unusual materials

False. We’ve screen printed on everything from satellites to wood to traditional print substrates. We get new materials to test out every week. So whether it’s an old or new substrate, we will help you pick the one that best fits your project.

12. There is no such thing as automated sheet-fed screen printing

False. We are constantly looking for ways to add efficiencies to our manufacturing supply chain, in this case we have implemented a fully automated large format sheet-fed UV curing screen printer, up to six colors in several lines.

13. Screen printing is an outdated technology

False. Just like other technologies screen printing continues to evolve and get more efficient. In the retail industry screen printing is still the fastest way to produce bulk-printed parts. In the industrial market screen printing is the only way to produce durable, highly reflective parts. In the electronic market, screen printing is the most durable and long-lasting method to print conductive ink.

14. You can’t print special effects

False. As one of the largest screen printers in the country, we take pride in our special effects printing. From distinctive textures and unusual substrates, to fragrance and metallic colors – we do it all! Here are some of the special effects we offer.

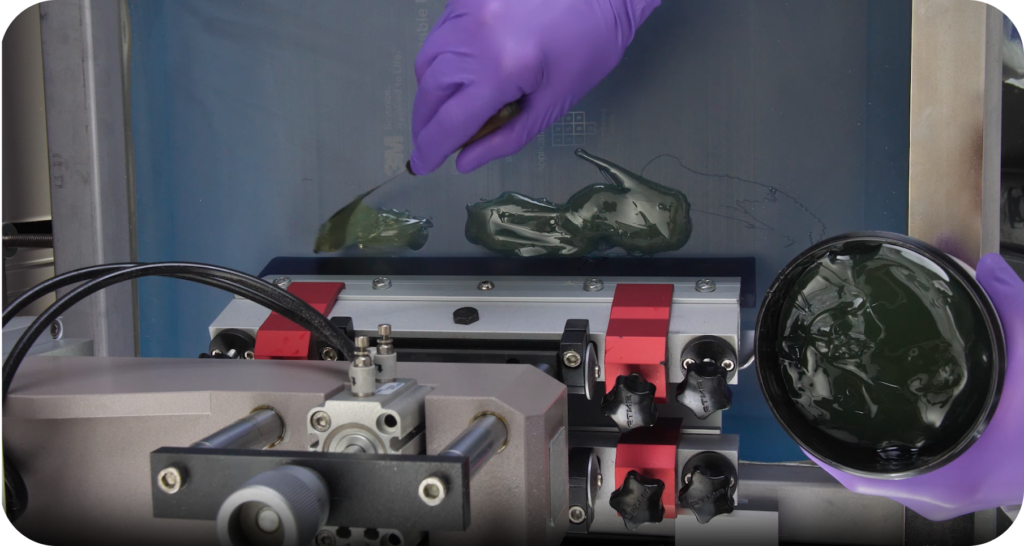

15. You can’t print adhesive

False. There are screen printable adhesives that allow us to print adhesive directly onto a part with bond lines as narrow as 0.5mm. Why do this over tape or other adhesive methods? It gives you more product versatility and increases efficiency by reducing the need to order hard tooling, die cut parts, and extract waste. Learn more here.

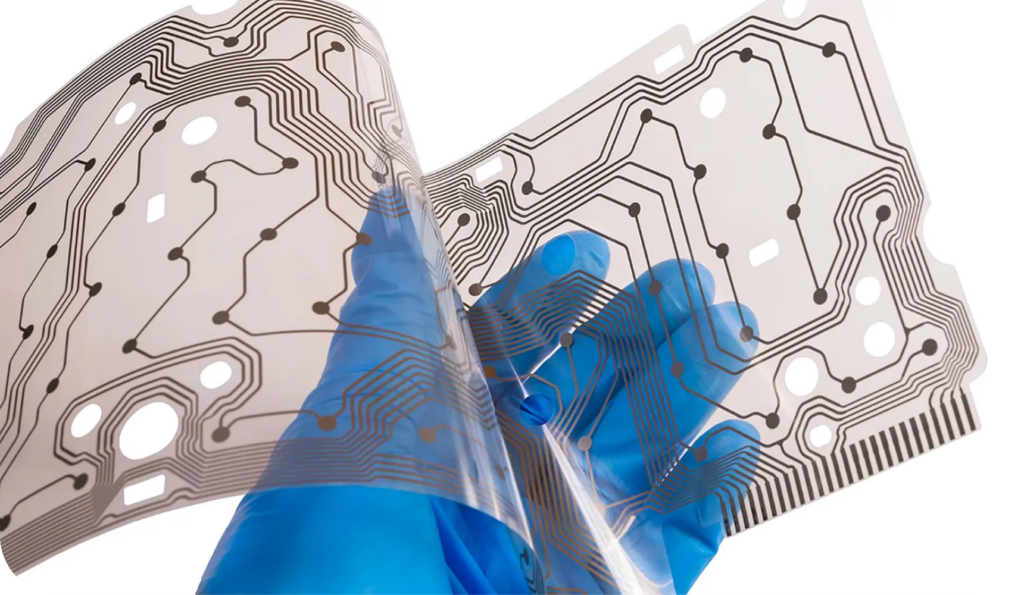

16. You can’t screen print on electronic devices

False. Printing conductive ink within parts has become very popular as devices become smaller and more flexible (conductive ink generates electrical conductivity between devices, replacing the wires and copper tracks in circuits). Learn more about conductive inks here.

17. Screen Printing is more expensive

False. Screen printing is more affordable and faster than digital printing when producing high quantities.

Grow your company’s revenue while personally enhancing your career! Screen printing is awesome, but it takes more than good artwork or a well-structured design to entice a consumer to buy a product. It’s a balanced recipe of great design, affordable manufacturing cost, clever placement, and judicious use of resources. Stay tuned for next month’s knowledge drop to learn more!

On the other hand, if you can’t wait or want to cure your screen printing issues RIGHT NOW – click here, and we’ll talk today!