We Saved A Super Car Paint Process With Custom Paint Masking

- Brand

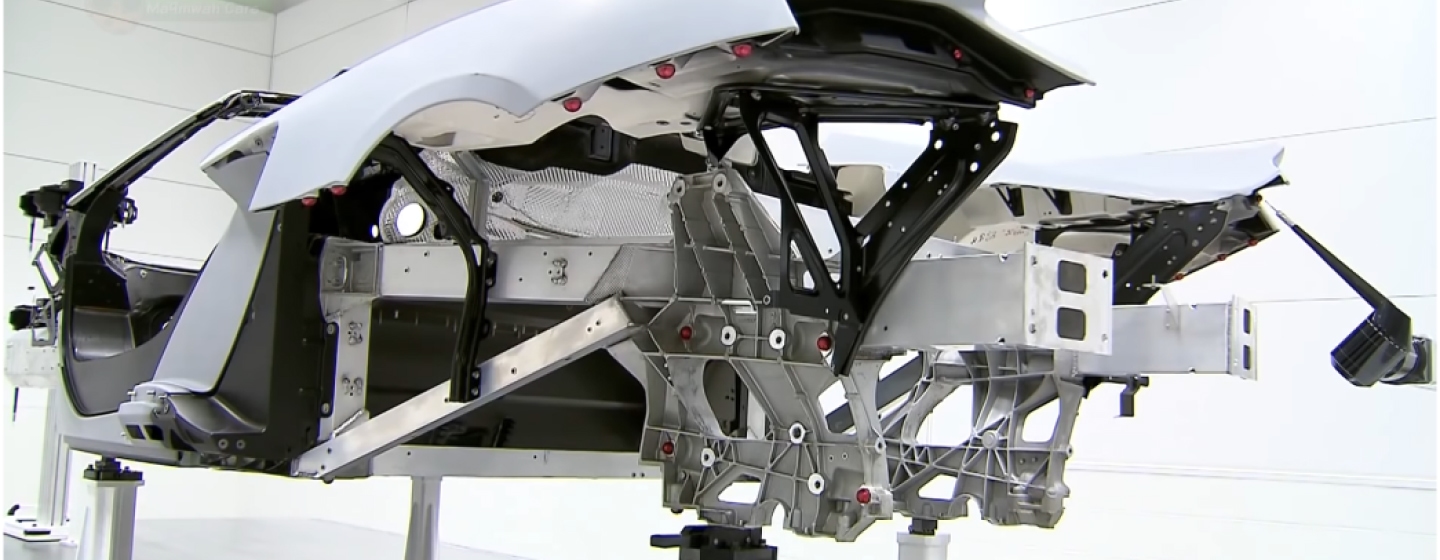

- Supercar Manufacturer

- Concept

Our customer came to us with many issues painting their headlight and taillight assemblies. They couldn’t get clean lines of paint and were scrapping out 70% of parts. They tried developing masking techniques but still couldn’t design a mask capable of clean paint lines, nor be removed without leaving residue, or keep a consistent application. The details in the parts were making it nearly impossible for the customer to get a uniform paint job. The parts continued to fail inspection and production schedule slowed.

01_Challenge

Design a mask that protects the paint, has consistent application, speeds up the assembly line, and ultimately decreases waste.

02_Solution

They had clean paint lines, easy to install/remove masks, and consistent application moving forward. The intricate design, yet simple masks were just what was needed to speed up their production and eliminate waste.

We created a simple mask that could be easily located and aligned based on the car parts. We also constructed a new operational procedure to enhance their current masking program and provided videos for installation.